Recipe and Batch Management Systems

NeoDyne offers both recipe and batch management systems, built on the Aveva Recipe Manager and InBatch platforms, respectively.

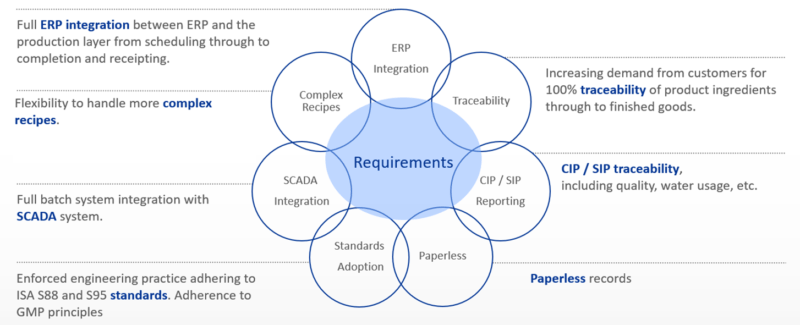

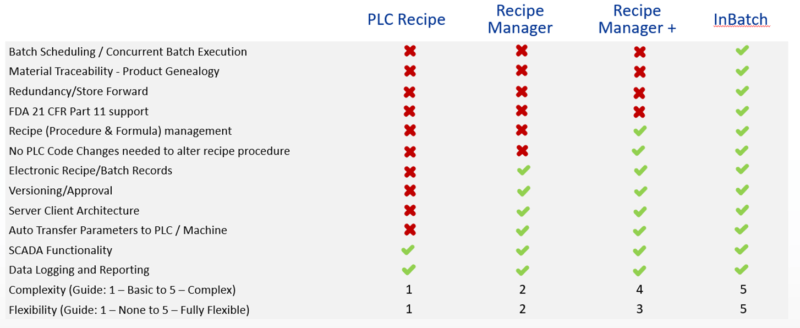

Although recipe management is critical to batch manufacturing, not every plant requires a full-blown batch management and control system. NeoDyne works with our customers to understand their requirements in detail and to recommend the right solution.

NeoDyne is an Endorsed AVEVA System Integrator.

Recipe Management

Aveva Recipe Manager Plus is a standalone recipe management system to help bridge the gap between HMI/SCADA and full batch management systems. It is a standardised, platform-independent software, designed to provide secure access to recipe and formula information.

Whether you are operating a batch production operation or a production line, the Aveva formula and recipe management software offers simplified recipe optimisation, deployment, adaptation, and execution.

The commerical off-the-shelf (COTS) Aveva software increases operational efficiency and flexibility by reducing product changeover time and enforcing product quality and repeatability through parameter download and procedure automation.

Batch Management

Aveva InBatch effectively manages flexible batch operations found in the process industries, including food and beverage/CPG. Adhering to the ISA-88 standards for batch control, it provides guidance and oversight to both recipe management and batch execution.

Batch Management software coordinates everything with the plant control systems, interfaces with the operators, and directs batch activity, material flow, and production data to a historical database for a full electronic batch record (EBR).

Batch Management software helps manufacturers to improve yields through increased product quality and operational efficiency. Automation of the batch processes delivers consistent quality to recipe specifications, maximises asset utilisation, helps eliminate paper records, and reduces batch release cycles. The control-system-neutral Batch management system allows for recipe and batch management standardisation across the business. This standardisation streamlines the new product introduction (NPI) process and helps you respond to changing market demands with greater agility.

Driving technology for leading brands

Integration & Digital Manufacturing Customers

We supply the Life Science, Food & Beverage, Data Centre and Energy industries.

Our key markets are for robust applications requiring innovation, reliability, longevity and specialised know-how.

Connect with a NeoDyne Engineer

Do you have a project

to discuss?

Are you facing an engineering challenge that requires expert guidance? Or a vision that needs to be brought to life? Meet our innovators, and together, we’ll shape tomorrow.